PRE-ENGINEERED BUILDINGS

INTRODUCTION

At Epicenter Consulting Engineers Pvt. Ltd., we bring specialized engineering consultancy expertise to a diverse range of Pre-Engineered Building (PEB) applications, serving industrial, commercial, and infrastructure sectors. Our portfolio includes car parking sheds, gas stations, factories, warehouses, showrooms, indoor stadiums, metro stations, and automobile manufacturing facilities. Each design is developed to optimize efficiency, durability, and aesthetic value while ensuring compliance with relevant codes and standards.

Backed by a multi-disciplinary team of experienced project managers, planners, engineers, designers, and 3D modelers, we provide end-to-end design services across Architectural, Civil, Structural, and Mechanical/Piping disciplines. Our approach emphasizes speed, cost-effectiveness, and ease of construction, enabling our clients to meet tight timelines without compromising quality. By combining technical excellence with practical, execution-focused solutions, we deliver PEB designs that are adaptable, economical, and built to perform in demanding operational environments.

OUR OFFERINGS FOR PEB SECTOR

Concept Design & Planning

- Layout optimization based on functionality and site constraints

- Architectural and structural concept design aligned with PEB standards

- Preliminary BOQs and cost estimation for budgeting and approvals

Detailed Design & Engineering

- Structural design of steel framing systems including primary and secondary members

- Foundation and substructure design suited for varied soil conditions

- Coordination of mechanical, utility, and architectural requirements

- Preparation of GA drawings, connection details, and fabrication-ready drawings

- 3D modeling and interference checks to ensure smooth fabrication and erection

Expansion & Brownfield Engineering

- Engineering support for PEB-based expansions, mezzanines, and retrofits

- Tie-in studies and integration with existing RCC or PEB structures

- Modifications for change of use, additional loads, or equipment accommodation

We bring industry-specific understanding, fast turnaround, and practical solutions that align with the modular nature and time-sensitive delivery model of PEB projects.

SPECIALIZATION

Car Parking

Our specialists have designed an extensive range of car park sheds, tailored to suit diverse site requirements and aesthetic preferences. These include simple single-bay structures as well as advanced configurations such as steel cantilever designs extending up to 5 meters in length. Each design prioritizes functionality, durability, and ease of maintenance, ensuring long service life with minimal upkeep.

All our car park structures are engineered to withstand their specified design cyclonic conditions without experiencing excessive deflections or sway. We follow applicable international and local design codes, standards, and regulatory requirements, ensuring safety, compliance, and reliability in all projects. This rigorous approach guarantees robust performance even in challenging environmental conditions.

As part of our core business focus on Industrial and Oil & Gas sectors, we do not undertake the design of multi-level car park buildings. This allows us to dedicate our expertise to specialized industrial structures where we deliver maximum value to our clients.

Factory Building

When designing the structural framework of a factory or workshop, we begin by thoroughly assessing all key parameters that influence performance and usability. This includes determining the overall building dimensions—length, width, and height—as well as evaluating specific operational needs such as crane and monorail systems, environmental conditions, and the requirement for effective roof and wall insulation. By understanding these factors in detail from the outset, we ensure that our designs are aligned with the functional, safety, and comfort needs of the facility.

Leveraging our extensive expertise in pre-engineered buildings (PEBs), warehouses, sheds, and shelters—both with and without integrated material-handling systems—we provide structural solutions that are cost-efficient while fully meeting the relevant design codes and standards for strength and serviceability. Our designs are developed with meticulous attention to technical accuracy, ensuring reliability and long-term performance even in demanding operational environments.

Beyond meeting technical specifications, our approach emphasizes the smart and efficient use of space. We select the most effective systems for access and circulation, enabling smooth workflow and enhanced productivity within the facility. Every project is customized to deliver durability, functionality, and adaptability, allowing our clients to maximize performance today while safeguarding value and sustainability for the future.

Gas Station

Our expertise in structural steel design allows us to seamlessly integrate innovative architectural concepts into safe, functional, and visually appealing gas station structures. We work closely with architects and clients, not only understanding their specific requirements but also providing valuable feedback on potential improvements and practical alternatives. Our approach ensures optimal space utilization and selection of the most efficient systems for access and circulation, creating layouts that are both user-friendly and operationally efficient.

We possess the capability to design space frames and space trusses using either open profile members or tubular sections such as CHS, SHS, and RHS, depending on project needs. This versatility enables us to cater to a variety of design aesthetics and structural performance criteria with comparative ease.

Backed by a highly qualified and motivated team, we bring engineering concepts to life with precision and efficiency, ensuring that each gas station structure meets the highest standards of durability, safety, and constructability.

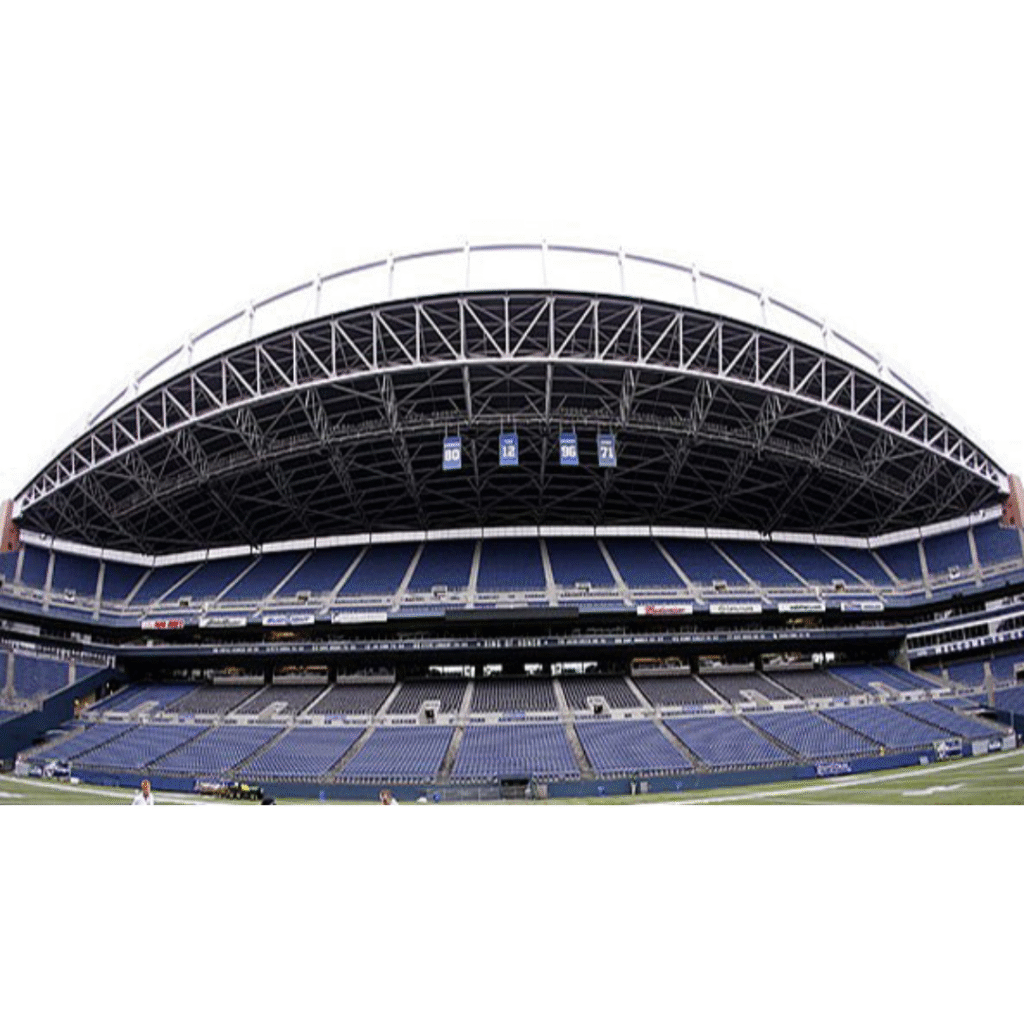

Indoor Stadium

ECE provides consulting services for athletic, recreation and fitness complex development. Whether you’re looking to develop a sports facility, stadium, recreation center or special events complex, we will support your project to minimise risks and maximise results. Our expertise with structural steel design enables us to blend ourselves comfortably to innovative architectural demands. We are capable of designing space frames and space trusses with both open profile members as well as tubular sections (CHS/ SHS/ RHS) with comparative ease. Our highly qualified team works with the keenness to decipher engineering into constructions.

Metro Station

At ECE, we bring together recognized specialists under one roof, collaborating closely with our trusted sub-contractors to deliver comprehensive metro station design and engineering solutions. Our expertise spans multiple disciplines—including structural, geotechnical, hydraulics, tunnelling, and maintenance—allowing us to address every technical requirement with precision. These capabilities are applied throughout all project phases, from initial planning and feasibility studies to commissioning and final handover.

Our proficiency in structural steel design enables us to adapt effortlessly to complex and innovative architectural demands typical of modern transit hubs. We design space frames and space trusses using both open profile members and tubular sections (CHS, SHS, RHS), offering flexibility in structural performance and aesthetic appeal.

Backed by a highly qualified and passionate team, we translate engineering expertise into practical, durable, and visually striking metro station structures, ensuring safety, efficiency, and long-term operational excellence.

Outdoor Stadium

ECE offers specialized consulting services for the planning, design, and execution of athletic, recreational, and fitness complexes, with a strong focus on outdoor stadium development. Whether the vision is to create a sports facility, multi-purpose stadium, recreation center, or special events venue, we provide the technical expertise and project management support needed to minimize risks and maximize performance. Our solutions are tailored to deliver functionality, durability, and audience comfort while meeting strict safety standards.

With extensive experience in structural steel design, we adapt seamlessly to bold and innovative architectural concepts. Our team is proficient in designing space frames and space trusses using both open profile members and tubular sections (CHS, SHS, RHS), enabling us to achieve both structural efficiency and striking aesthetics.

Guided by a highly skilled and motivated team, we transform engineering concepts into high-quality outdoor stadium structures that inspire, endure, and perform for decades.

Showroom

Our custom-designed Pre-Engineered Building (PEB) concepts offer innovative and efficient solutions for a wide range of fast-track projects, including showrooms that demand both functionality and architectural appeal. By combining our deep expertise in PEB design with the ability to work confidently with tapered and tubular member profiles, we adapt seamlessly to creative and unconventional architectural visions. We work closely with architects and clients, providing constructive feedback on possible improvements and practical alternatives to enhance the final outcome.

Our capabilities extend to designing space frames and space trusses using both open profile members and tubular sections (CHS, SHS, RHS), enabling us to meet varied structural and aesthetic requirements with ease.

With a highly qualified and dedicated team, we focus on optimizing space usage and implementing the most effective systems for access and circulation, delivering showroom structures that are efficient, visually striking, and built to last.

Distribution Center

Designing a high-performance distribution center requires seamless coordination of architectural, structural, and MEP engineering to meet fast-paced logistics and automation demands.

Architecturally, layouts focus on maximizing storage density and streamlining goods movement, with dedicated zones for inbound, outbound, packaging, and sorting.

The structural design is central to the facility’s functionality—long-span steel frames are used to eliminate internal columns, enabling uninterrupted racking layouts and smooth flow of autonomous systems. High-bay structures (12–18 meters or more) accommodate vertical storage and mezzanine levels for picking and sorting operations. Floor slabs are meticulously engineered for high load-bearing capacity, minimal deflection, and superior flatness (FM2 or better) to support heavy forklift loads and autonomous mobile robots (AMRs).

MEP systems integrate energy-efficient lighting, HVAC for thermal comfort, and robust electrical infrastructure to support conveyors, sorters, and automation. Our integrated approach ensures reliability, scalability, and compliance with global warehousing standards.

Seeds Pack Facility

Our seeds processing plants integrate hygienic architectural zoning – segregating raw intake, drying, grading, treatment, and packing zones with epoxy-coated walls (FSSAI-compliant) and positive-pressure airlocks to prevent cross-contamination. Structurally, vibration-isolated RCC floors (IS 456:2000) support high-speed optical sorters and automated weigher-fillers, while steel mezzanines with grating decks enable overhead conveyor access. Roof structures feature explosion relief panels (NFPA 68) above treatment chambers handling combustible seed dust.

Critical MEP systems include:

- Climate-controlled storage: HVAC maintaining 15–18°C/50–60% RH (ASHRAE 90.1) via desiccant dehumidifiers and HEPA filtration.

- Dust management: Centralized aspiration networks (NFPA 61) with cyclone separators achieving 99% capture.

- Automation-ready electrical: ATEX-rated lighting, isolated earthing for sensitive grading sensors, and UPS-backed cold rooms.

Infrastructure prioritizes utility corridors for seed pneumatic transport lines and firewater ring mains. We enforce BIM coordination to embed MEP within structural elements, ensuring compliance with APEDA norms, NBC 2016 fire codes, and seismic resilience (Zone III/IV).

Cold Storage

Designing a cold storage warehouse demands integrated architectural, structural, and MEP engineering expertise.

Architecturally, thermal insulation and vapor barriers are critical to maintain low temperatures, minimize energy loss, and prevent condensation.

Structural systems must support heavy racking loads and accommodate temperature-induced material expansion/contraction—steel framing with insulated panel systems is typical. Floor slabs are engineered with vapor barriers, insulation, and glycol-based underfloor heating to prevent frost heave.

MEP systems are central to performance: HVAC systems include industrial-grade refrigeration units with redundancy and zoning controls; electrical systems must handle high loads and provide backup power; and plumbing must prevent pipe freezing. Fire protection often uses dry-pipe systems suited for sub-zero environments. Our firm’s integrated design approach ensures operational efficiency, compliance with international food safety standards, and long-term facility resilience.