INDUSTRIAL

INTRODUCTION

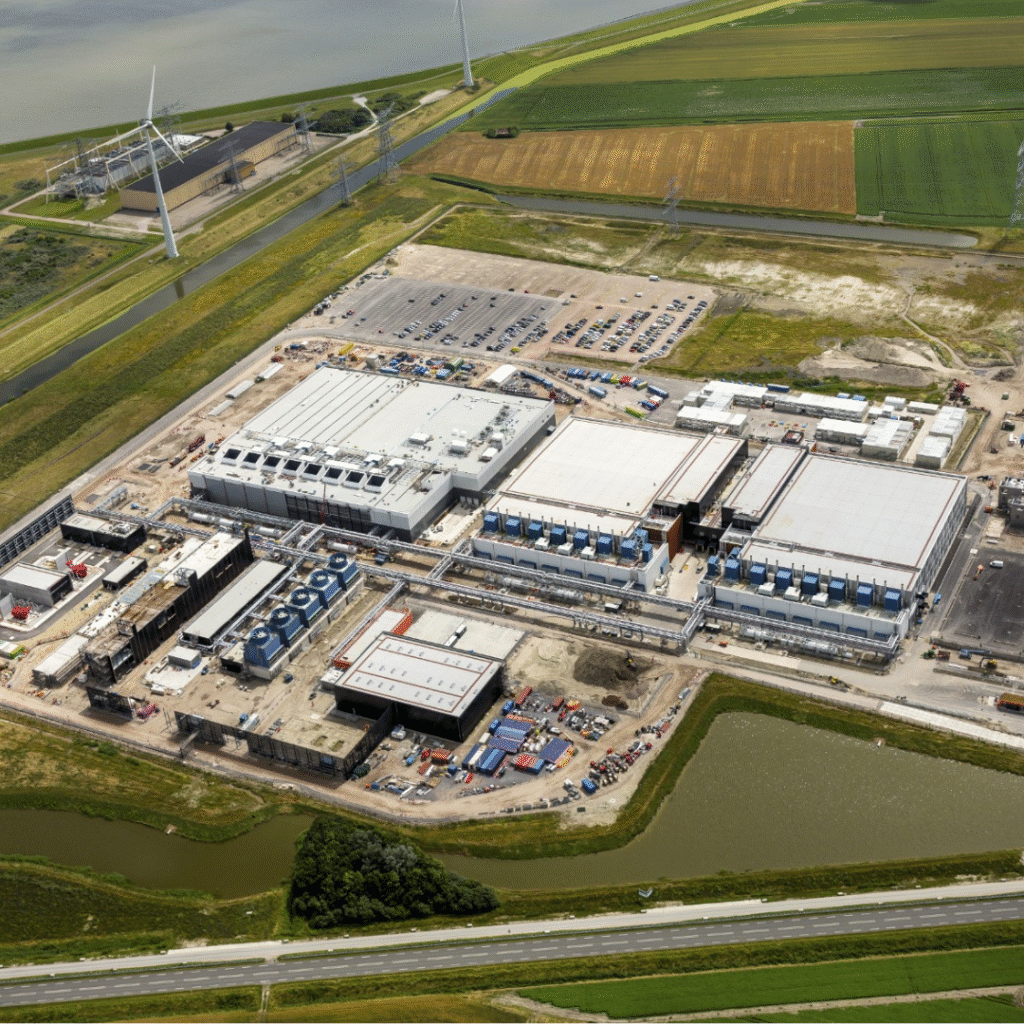

At Epicenter Consulting Engineers Pvt. Ltd., we deliver comprehensive, multi-disciplinary engineering consultancy services for a broad spectrum of industrial facilities, including cement plants, manufacturing units, process plants, rice mills, substations, and other large-scale factory operations. Our strength lies in providing end-to-end solutions that integrate seamlessly across all project stages from concept and feasibility studies to detailed design and execution support. Backed by a dedicated team of experienced project managers, planners, engineers, designers, and skilled 3D modelers, we operate across multiple core disciplines such as Architectural, Civil, Structural, and Mechanical/Piping engineering. Every project we undertake is guided by a commitment to quality, precision, and efficiency, ensuring that our clients receive execution-focused designs that are both technically sound and optimized for cost-effectiveness, safety, and long-term performance.

OUR OFFERINGS

Pre-Engineering & Planning

- Site master planning and utility layout optimization

- Feasibility studies and cost estimation

- Equipment layout planning for process and support systems

Detailed Engineering & Design

- Civil, structural, and architectural design of buildings, foundations, and equipment supports

- Mechanical and piping system design for utilities, process equipment, and material handling

- Preparation of construction drawings, 3D modeling, and coordination with OEMs

Brownfield Modifications & Plant Expansion

- Engineering for plant upgrades, retrofits, and production line expansions

- As-built documentation and integration of new systems with existing infrastructure

- Shutdown planning and constructability assessments for minimum disruption

SPECIALIZATION

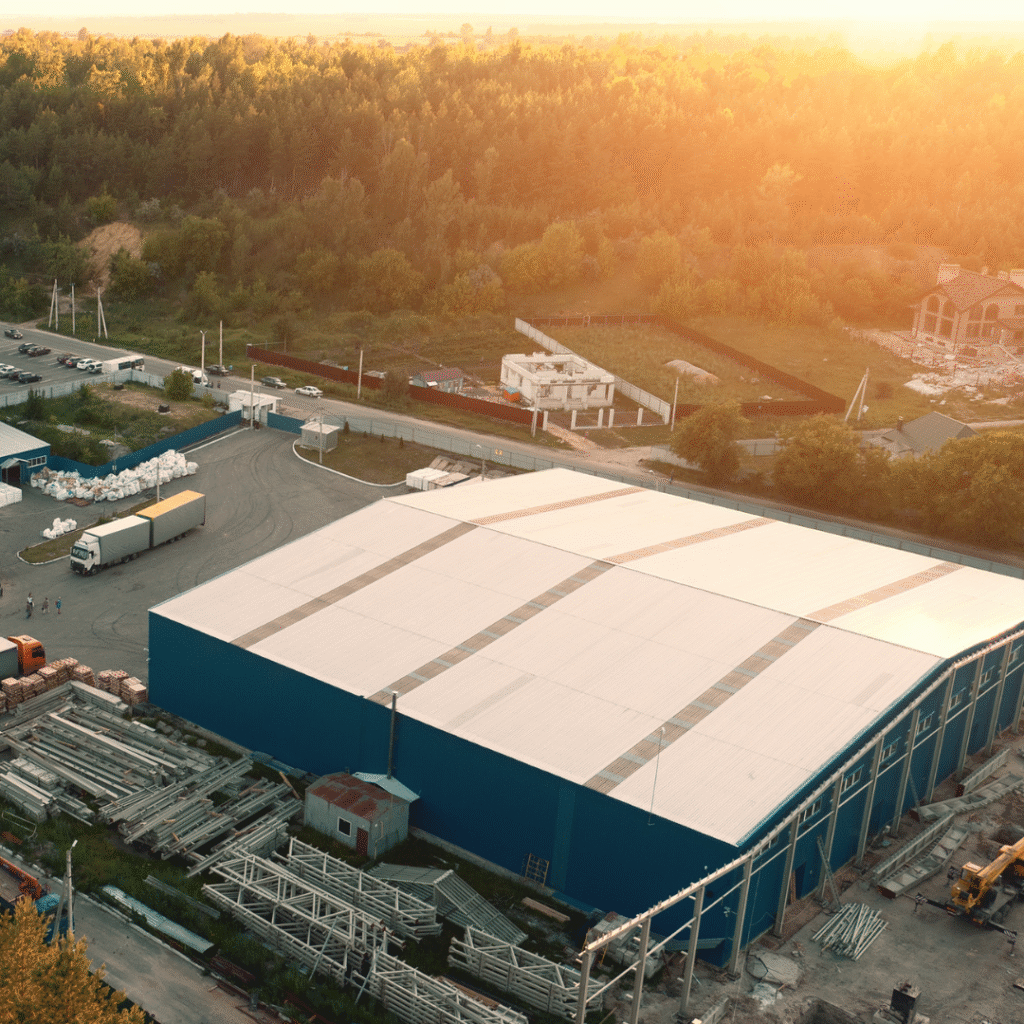

Factory Building

When designing the structural framework of a factory or workshop, we begin by thoroughly assessing all key parameters that influence performance and usability. This includes determining the overall building dimensions—length, width, and height—as well as evaluating specific operational needs such as crane and monorail systems, environmental conditions, and the requirement for effective roof and wall insulation. By understanding these factors in detail from the outset, we ensure that our designs are aligned with the functional, safety, and comfort needs of the facility.

Leveraging our extensive expertise in pre-engineered buildings (PEBs), warehouses, sheds, and shelters—both with and without integrated material-handling systems—we provide structural solutions that are cost-efficient while fully meeting the relevant design codes and standards for strength and serviceability. Our designs are developed with meticulous attention to technical accuracy, ensuring reliability and long-term performance even in demanding operational environments.

Beyond meeting technical specifications, our approach emphasizes the smart and efficient use of space. We select the most effective systems for access and circulation, enabling smooth workflow and enhanced productivity within the facility. Every project is customized to deliver durability, functionality, and adaptability, allowing our clients to maximize performance today while safeguarding value and sustainability for the future.

- Overall building dimensions viz. length, width and height.

- Crane requirements.

- Environmental conditions.

- Roof/ wall insulation.

Pharma/Biotech

Designing facilities for the pharma and biotech industry requires highly specialized architectural, structural, and MEP engineering to support complex research, production, and regulatory requirements. Though both sectors share similar goals—precision, safety, and compliance—their facility needs can differ in scale and process flow.

Architecturally, both facility types demand stringent contamination control, cleanroom classifications (ISO or Grade A–D), and unidirectional flow of personnel and materials. Finishes must be smooth, non-porous, and easy to sterilize. Pharma facilities often include large-scale formulation, filling, and packaging areas, while biotech labs focus more on upstream/downstream biologic processing and smaller-scale R&D.

Structurally, vibration-sensitive zones (e.g., labs, cleanrooms) may require isolated foundations or dampened floor systems. Facilities must also support heavy process equipment and be flexible for future process reconfiguration.

MEP systems are critical: precise HVAC zoning with HEPA filtration and pressure differentials, redundant power systems, purified water loops (WFI, RO), clean steam, gas lines, and hazardous waste containment.

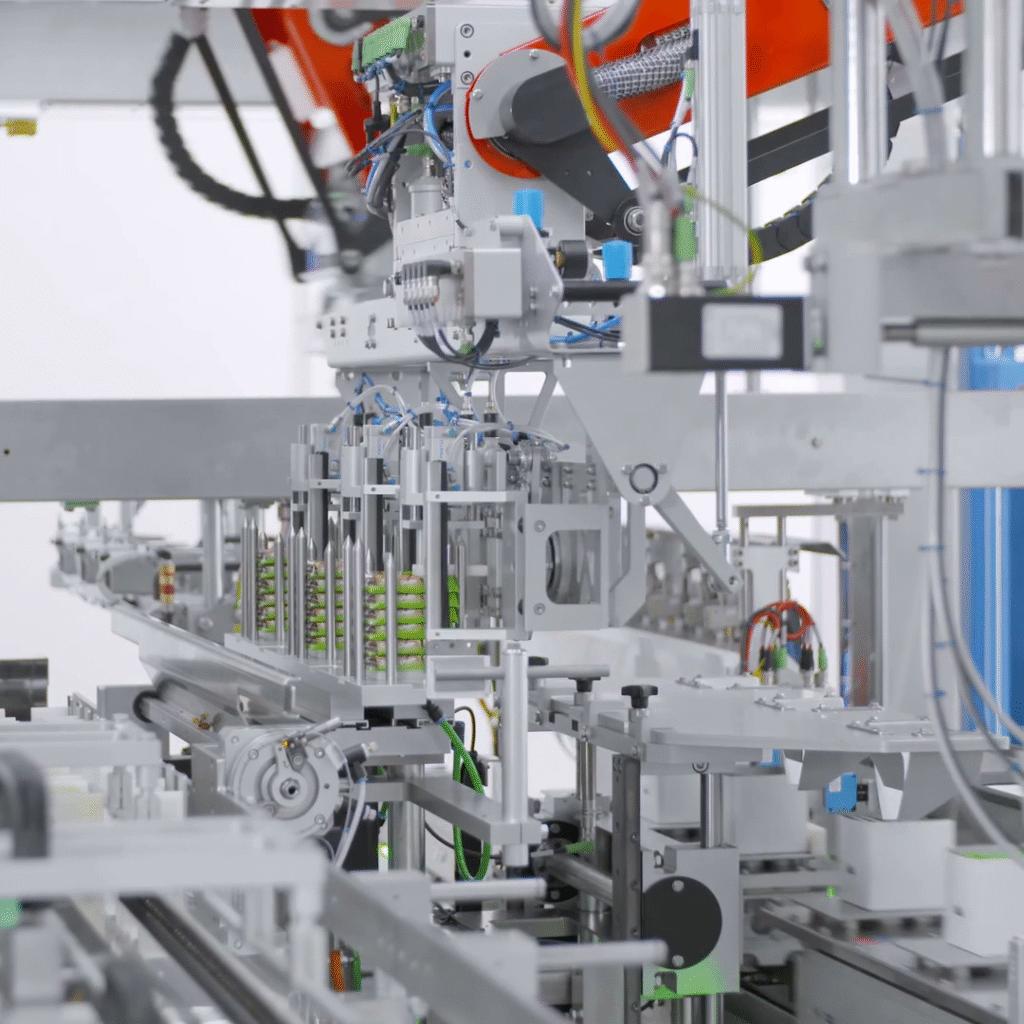

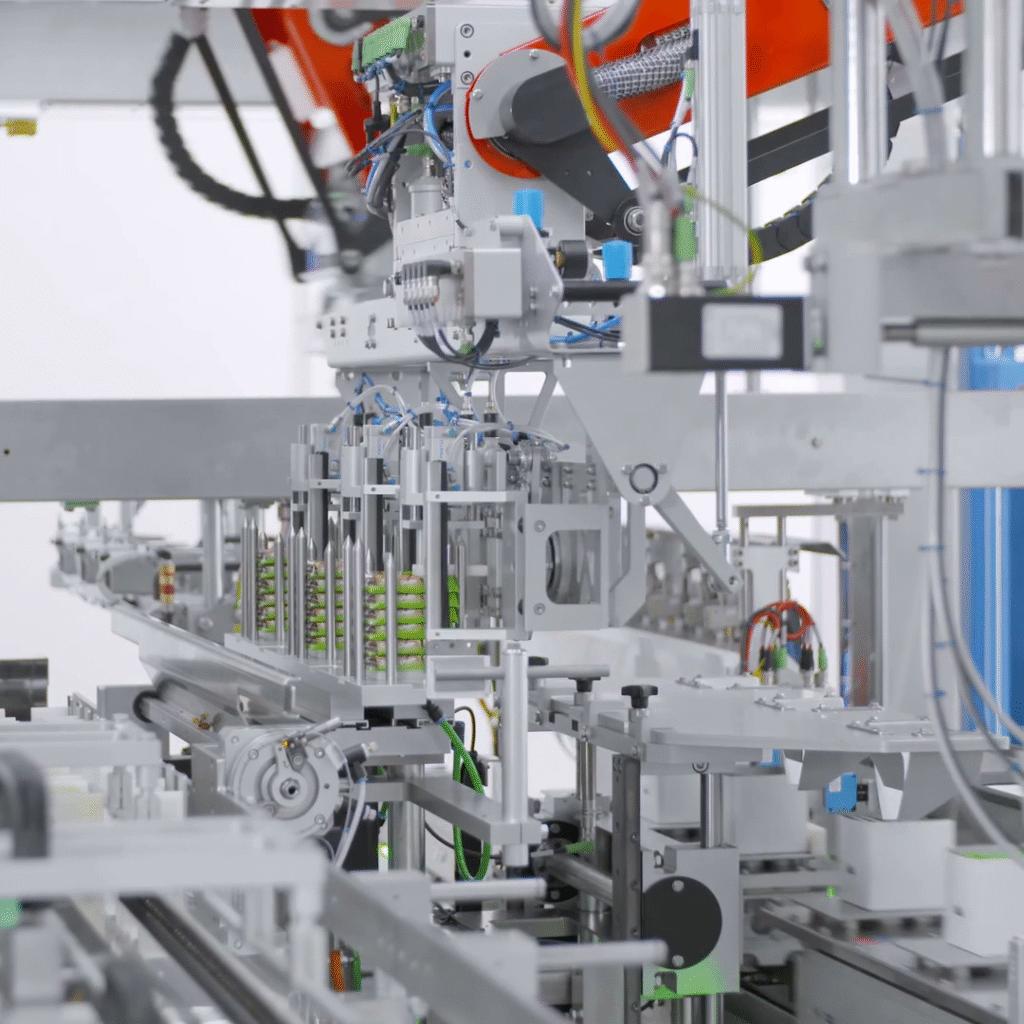

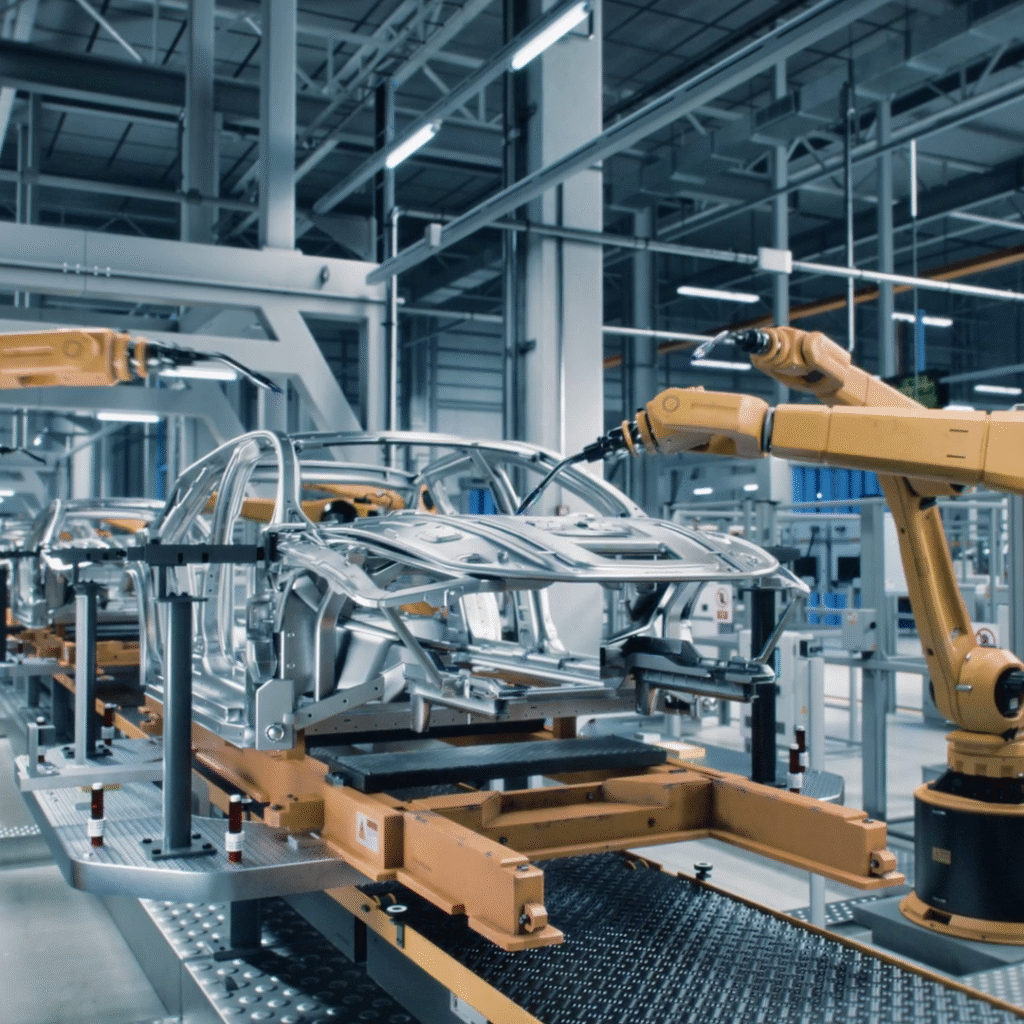

Vehicle Integration Unit

Our VIU structures employ high-strength reinforced concrete foundations (IS 456:2000) with pile caps and ground beams to withstand dynamic loads from robotic assembly lines (50 kN/m²) and 50-ton overhead cranes. The structural frame combines hot-rolled steel columns (IS 2062 Grade E250) with rigid moment-resisting connections (AISC 360-16) for seismic resilience (Zone IV per IS 1893), while long-span roof trusses (40m clear spans) accommodate uninterrupted production zones. Critical features include:

- Vibration-damped floors with isolation joints between static/dynamic machinery areas.

- Heavy-duty crane runways (CMAA Class D) with galvanized rail beams and deflection control (<L/600).

- Reinforced utility trenches (1.5m depth) for electrical/data conduits and compressed air lines.

- Explosion-resistant walls (NFPA 68 blast relief panels) around fuel/battery testing cells.

Architectural integration ensures 9m clear heights for gantry access and retractable roof panels for oversized component installation.

Rice Mill

A modern rice mill demands a comprehensive structural and civil engineering approach to support heavy-duty processing units — pre-cleaners, de-stoners, polishers, graders, and multi-tier storage bins — all mounted on vibration-isolated RCC foundations and explosion-resistant steel framing designed for dynamic machinery and dust-prone zones.

ECEPL’s plant layout and structural design expertise ensures an optimized production flow from paddy intake to finished packaging, integrating parboiling, drying, milling, and storage zones with elevated service decks, inspection platforms, and ventilation corridors for safe and efficient operation.

Our team specializes in the design of heavy equipment foundations, including silo bases, soaking tanks, elevators, conveyors, and storage vessels, addressing complex load combinations, settlement control, and dynamic response through robust RCC and steel support systems.

Each project adheres to IS and industry standards, ensuring structural stability, durability, and operational reliability while harmonizing process, safety, and infrastructure within a unified, buildable design framework.

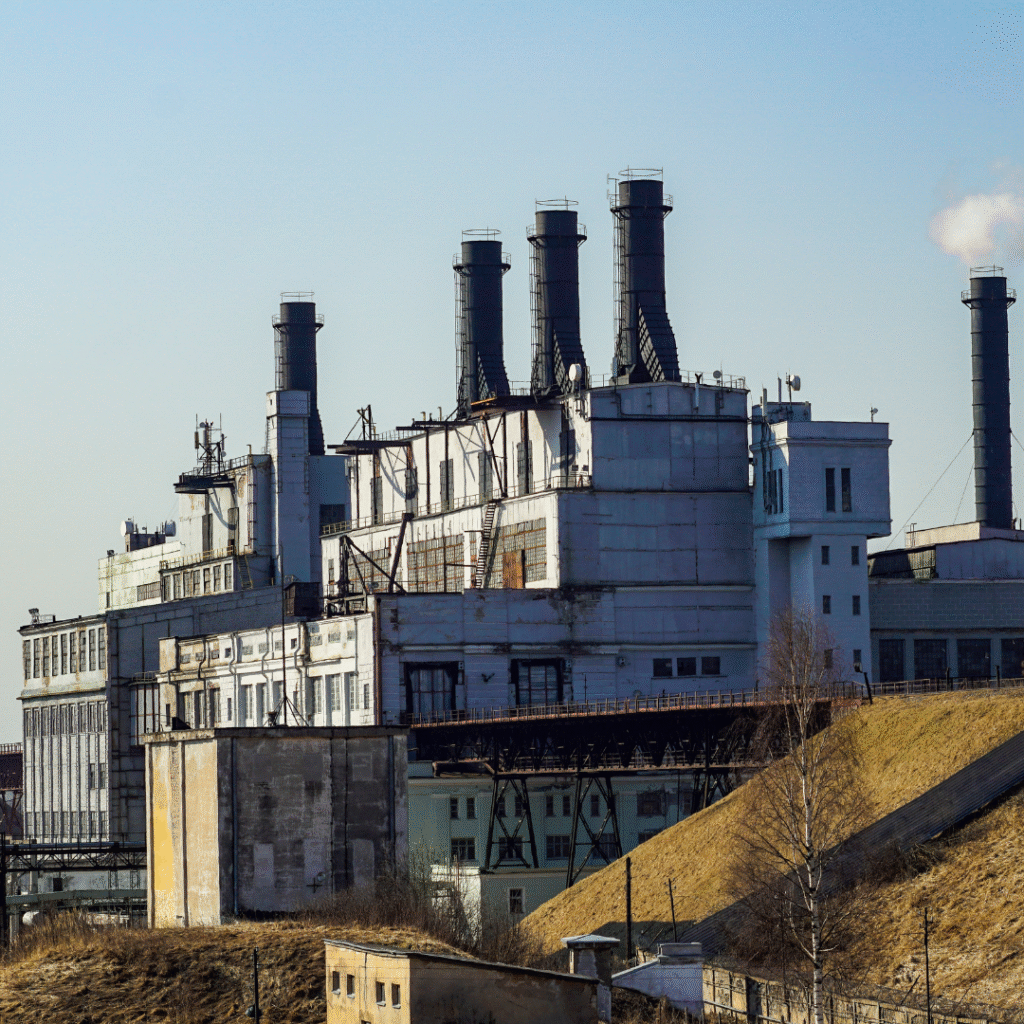

Cement Plant

Cement Plant: We offer specialized structural engineering solutions for cement plants, addressing every critical element of these highly demanding industrial facilities. Our scope of expertise covers the design and engineering of robust silos, high-performance pre-heater towers, kiln support structures, and heavy-duty vertical mill foundations. Each of these components is planned with precision, ensuring they meet the unique operational needs and challenges posed by cement manufacturing environments.

In addition to the core plant structures, we excel in designing transfer towers and conveyor systems that are tailored to specific site layouts and production requirements. Every design we produce is guided by the principles of strength, stability, and long-term durability, enabling reliable performance under heavy loads, continuous operations, and extreme environmental conditions. Our designs comply fully with relevant industry codes and standards, ensuring both safety and efficiency.

By applying proven engineering methodologies and leveraging our extensive experience in heavy industrial environments, we help clients achieve consistent operational excellence. Our focus extends beyond immediate project delivery to long-term maintainability, ensuring that facilities remain dependable and cost-effective for decades. This commitment to performance, safety, and sustainability has earned us a reputation for delivering engineering solutions that stand the test of time.

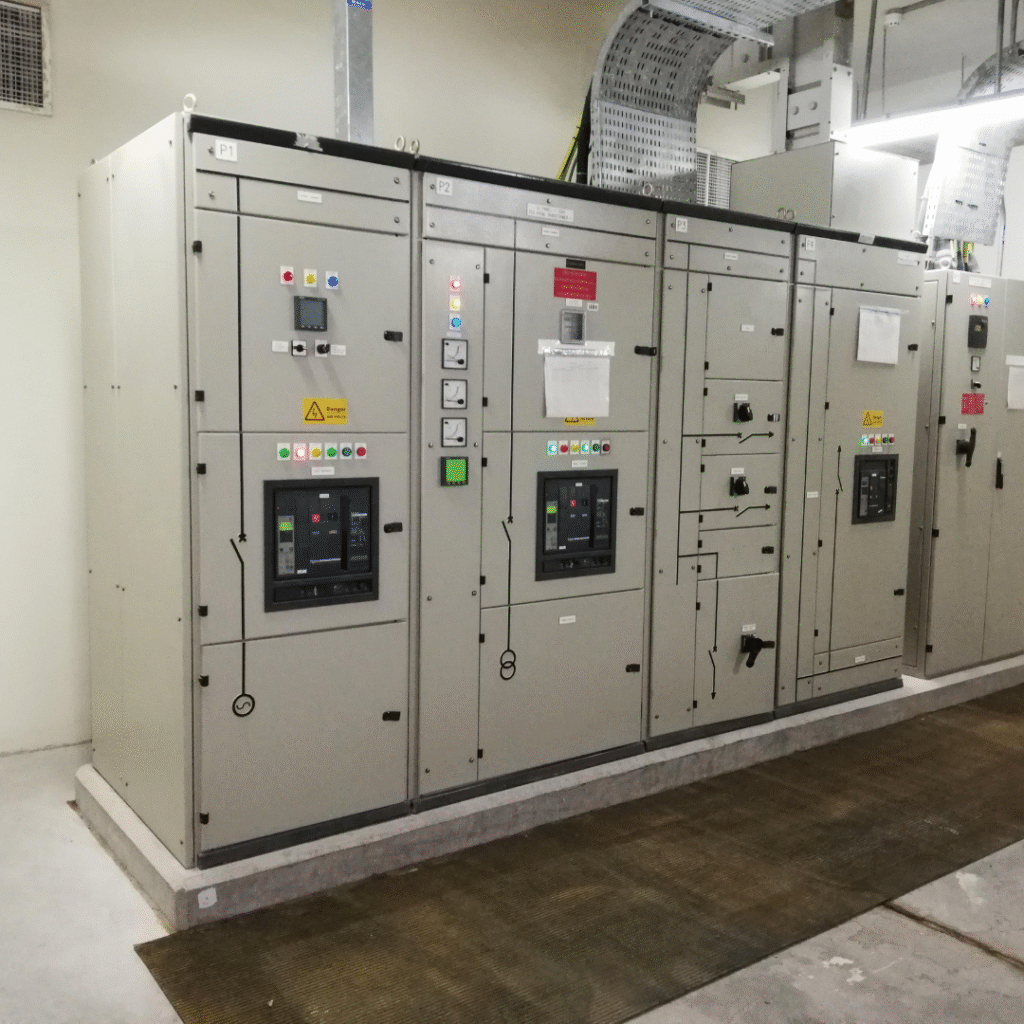

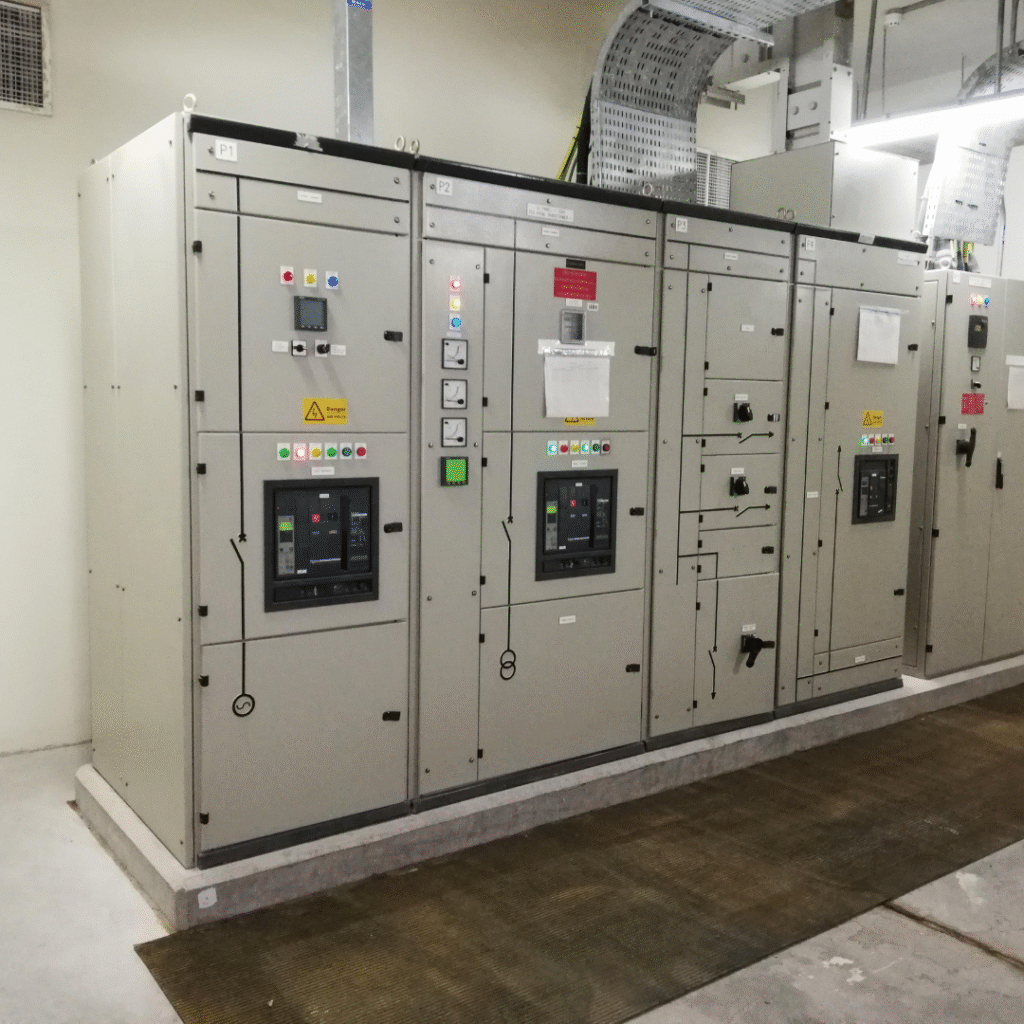

Substation Building

Partner with us for precision-designed substation buildings in critical oil & gas facilities. We deliver integrated structural, architectural, and MEP solutions tailored to stringent industry standards. Our specialists can design robust framed structures, sometimes exceeding 100m in length, optimizing layouts for essential zones: battery rooms, switchgear rooms, Local Equipment Rooms (LER), and electrical panel spaces.

We meticulously address unique requirements: seismic-resistant floor cutouts, strategic expansion joints, reinforced corner angles/channels, and specialized floor finishes. DG sets are seamlessly integrated under rear-side sheds, structurally tied to main columns. For cable management, we design efficient multi-tier tray systems, whether buried or suspended from cellar slabs using engineered supports like Hilti and other anchors.

Our meticulous foundation design, using customised design tools from sub-structure design, has proven to reduce construction costs by up to 30% while ensuring unparalleled safety and reliability. From concept to commissioning, we engineer substations that prioritize resilience, operational efficiency, and lifecycle value.