UNDER-GROUND/ FOUNDATION

INTRODUCTION

At Epicenter Consulting Engineers Pvt. Ltd., we provide specialized engineering solutions for a wide range of underground structures and foundation systems, tailored to meet the demands of industrial, commercial, and infrastructure projects. From designing an isolated footing for a warehouse to engineering a robust block foundation for a reciprocating compressor, our team has the expertise to handle foundations of any scale or complexity.

Our extensive experience covers driven and bored piles, flexible and rigid rafts, tank and stack foundations, retaining walls, underground pits, trenches, pipe sleepers, combined footings, strip footings, and isolated footings. Each design is developed in compliance with relevant codes and site-specific geotechnical conditions, ensuring safety, durability, and cost efficiency. By integrating structural integrity with constructability, we deliver underground solutions that perform reliably and support long-term operational success.

OUR OFFERINGS

Architectural & Structural Design

- RCC design for residential buildings, commercial complexes, and institutional facilities

- Structural analysis and design of beams, slabs, columns, shear walls, and staircases

- Planning and detailing of water tanks, lift cores, ramps, and balconies

- Preparation of architectural layouts, working drawings, and municipal submission packages

Substructure & Foundation Engineering

- Shallow and deep foundation design (isolated, combined, raft, and pile foundations)

- Machine foundation design for equipment loads and dynamic behavior

- Design of retaining structures, basement walls, and diaphragm walls

- Structural detailing for waterproofing, dewatering pits, sumps, and trenches

Structural Modifications & Additions

- Retrofit and strengthening of existing RCC structures

- Engineering for vertical or lateral expansion of buildings

- Seismic checks, stability evaluations, and rehabilitation support

SPECIALIZATION

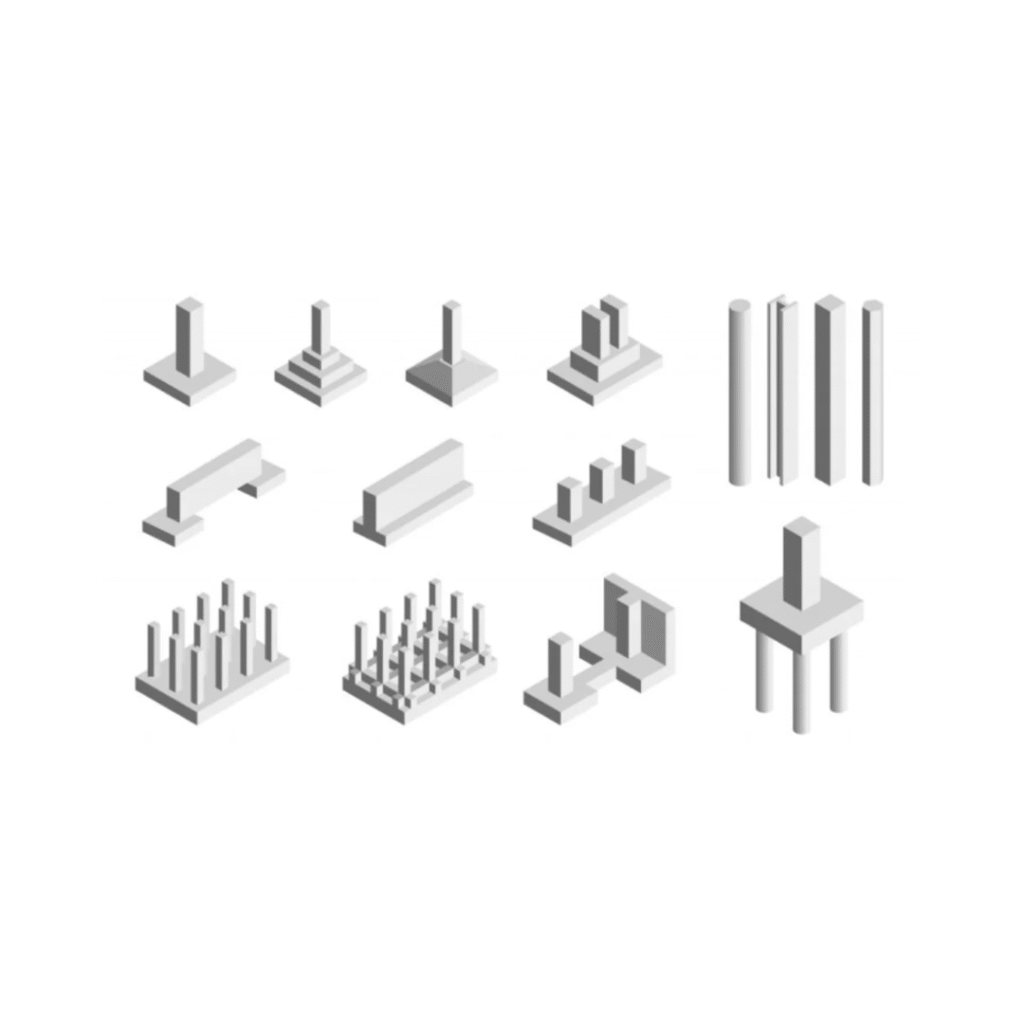

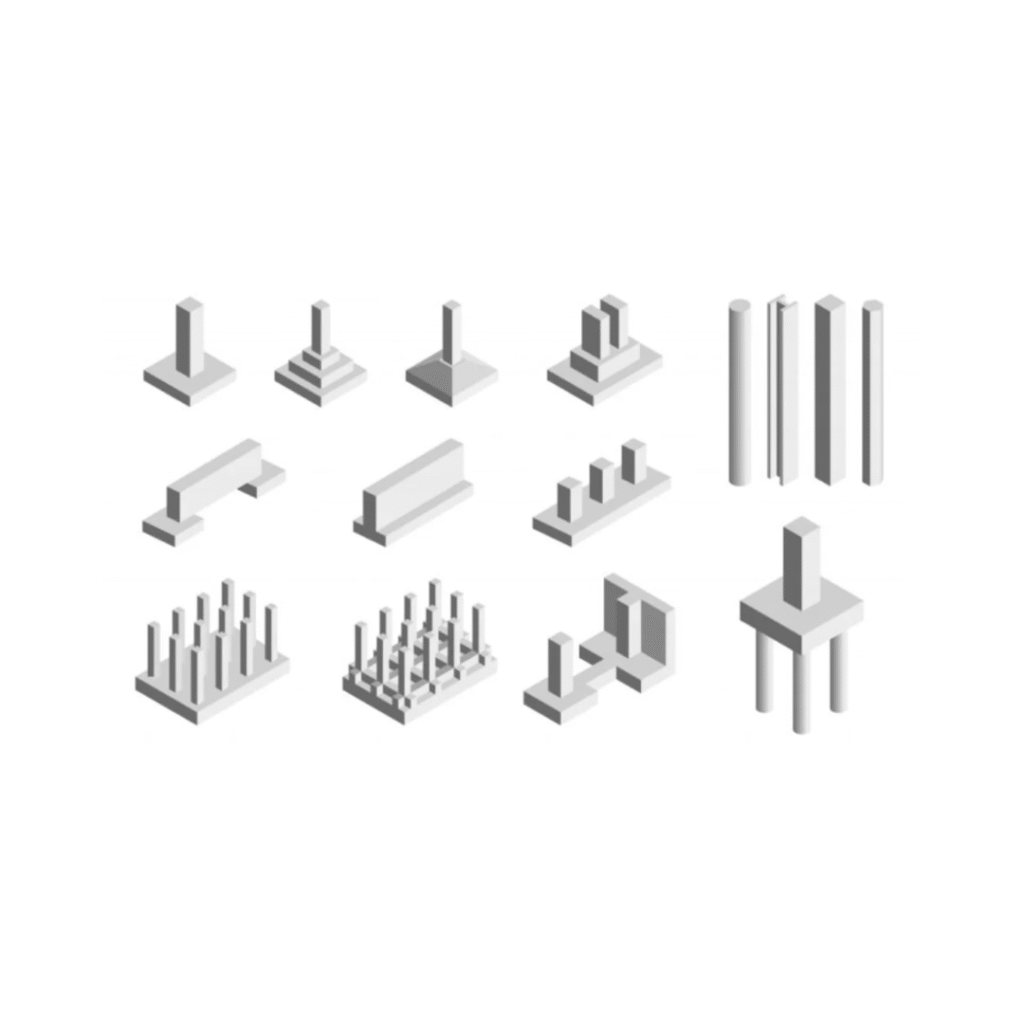

Shallow Foundation

Shallow foundations including spread footings, combined footings, and mat (raft) foundations are critical structural systems designed to transfer building loads directly to the ground near the surface. Structural design is central to ensuring stability, uniform load distribution, and resistance to settlement.

Spread footings are commonly used under individual columns where soil has adequate bearing capacity. Combined footings support two or more columns when they are closely spaced or near property lines. Mat foundations are suitable for heavy structural loads or weak soil conditions, distributing loads over a large area to minimize bearing pressure and differential settlement.

Each system is designed based on detailed geotechnical analysis, load combinations, and serviceability criteria. Our structural engineering approach ensures reliable, code-compliant shallow foundations tailored to site-specific soil profiles and performance requirements.

Deep Foundation

Deep foundations such as piles, pile caps, and piers are essential structural systems used when surface soils lack the strength to support building loads. Structural design is crucial for ensuring safe load transfer to deeper, stable strata, often located several meters below ground level.

Piles, whether cast-in-situ or driven precast, are selected based on load requirements, soil conditions, and project constraints. They resist both vertical and lateral loads and are typically grouped with pile caps that distribute superstructure loads uniformly.

Pile caps are heavily reinforced to handle concentrated forces and maintain structural integrity. Detailed structural analysis considers axial loads, bending, group effects, and settlement behavior.

Deep foundation systems are commonly used in high-rise buildings, industrial structures, and bridges where load intensity or soil limitations demand deeper support.

Our team designs robust, code-compliant deep foundations that ensure long-term stability, structural safety, and optimal performance in challenging ground conditions.

U/G Pit

At ECE, we bring proven expertise in the design of underground pits, sumps, and tanks across a wide range of industrial and utility applications. Our engineering solutions are tailored to meet site-specific conditions, ensuring durability, functionality, and compliance with operational requirements for varying depths, lengths, and widths. With extensive design experience, our team has successfully executed underground pits reaching depths of up to 10.5 meters.

We are well-versed in the specialized needs of different storage systems including molten sulphur, amine sumps, oily water, sewage, and potable water. Each design considers load-bearing requirements, soil-structure interaction, water tightness, and long-term performance under diverse operating conditions.

Our capabilities extend to open-top pits as well as those covered with monolithic RCC slabs, precast RCC slabs, gratings, or chequered plates. By integrating structural precision with practical construction methodologies, we deliver safe, reliable, and cost-efficient underground storage solutions for our clients.

U/G Trench

At ECE, we offer specialized expertise in the design of underground trenches tailored to diverse industrial and infrastructure requirements. Our team has the technical capability to engineer trenches of any width, depth, shape, or slope, ensuring safe, functional, and durable solutions suited to site-specific conditions. Each trench is designed with a focus on structural integrity, ease of construction, and long-term performance.

We have successfully delivered trench designs for a variety of applications including storm water drainage, oily water collection, electrical and instrumentation cable routing, as well as process piping systems. Our designs incorporate careful consideration of soil interaction, load distribution, hydraulic behavior, and service accessibility to ensure reliability under varying operational demands.

Our experience spans open-top trenches and those covered with monolithic RCC slabs, precast RCC slabs, gratings, or chequered plates. By combining engineering precision with constructability insights, ECE delivers cost-effective trenching solutions that seamlessly integrate with the overall project infrastructure.

Retaining Structures

At ECE, we approach the design of retaining structures with a strong foundation in geotechnical understanding and site-specific analysis. By integrating soil investigation data with advanced engineering tools, we ensure that every solution is tailored to achieve stability, durability, and long-term cost efficiency. Special attention is given to factors such as fluctuating water table conditions, active and passive earth pressures, surcharge loads, and seismic impacts, all of which are critical for ensuring reliable performance.

Our expertise covers a wide spectrum of applications including cantilever and counterfort walls, culverts, trench walls, wing walls, embankments, and slope protection systems for reclaimed or geotechnically challenging lands. Each structure is engineered to withstand environmental demands while maintaining functional and aesthetic integration with the broader infrastructure.

We emphasize constructability and material optimization, incorporating effective drainage provisions to reduce hydrostatic pressures and extend service life. By combining structural precision with practical execution strategies, ECE delivers retaining solutions that prioritize safety, efficiency, and seamless incorporation into overall project development.

Shorting & Strutting

Effective shoring and strutting systems are engineered to temporarily retain soil and groundwater during deep excavations, ensuring adjacent structure stability and worker safety.

Key considerations begin with site-specific soil mechanics, analyzing cohesion, groundwater flow, and surcharge loads from nearby traffic or buildings. The design selects optimal wall types (sheet piles, secant walls, or soldier beams) and strategically spaces pre-stressed struts or ground anchors to resist lateral earth pressures while controlling deflection.

Real-time monitoring (inclinometers, strain gauges) validates performance, and rigorous sequencing installing supports incrementally as excavation progresses prevents soil relaxation.

Compliance with codes (BS 5975, EN 1997-1) enforces safety margins (FOS ≥1.5), making these temporary structures a critical fusion of geotechnical insight and precision structural engineering.

Dewatering

Effective dewatering systems are engineered to manage groundwater and pore pressure during excavations, ensuring stable soil conditions and safe construction.

Key design begins with site-specific hydrogeology viz. mapping aquifer depth, permeability (k-values), and recharge rates to select optimal methods: wellpoints for shallow sands, deep wells for confined aquifers, or vacuum-assisted systems for silts.

Precise pump sizing (based on inflow calculations) and filtered discharge (meeting EPA/ISO 14001 standards) prevent settlement or contamination. Real-time monitoring (piezometers, flow meters) validates drawdown targets while safeguarding adjacent structures.

Strategic implementation, phasing well installation with excavation, balances water table control with structural integrity, turning saturated ground into workable space through calculated water extraction.